Moisture control |

|

|

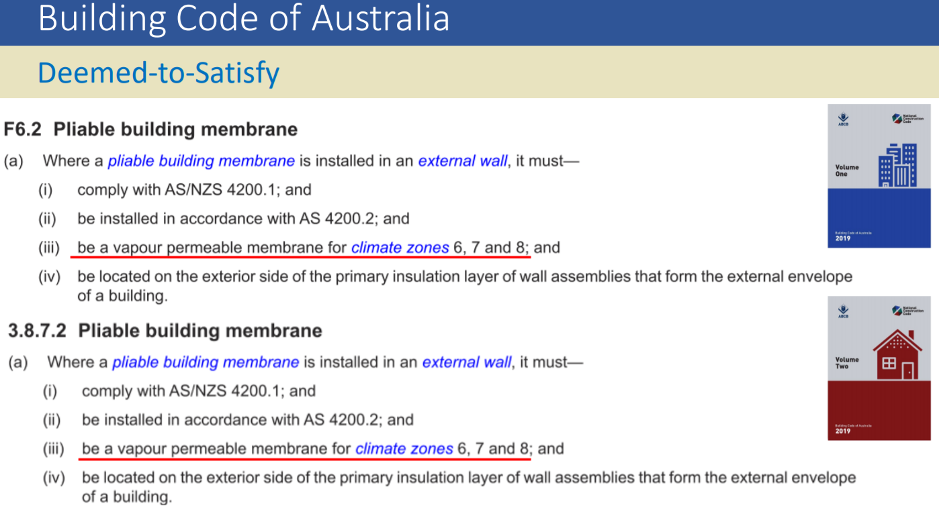

This project involves investigating the role of the NCC in mitigating the risk of condensation in residential buildings. It is being carried out in response to feedback from industry and building regulators. After introducing initial condensation provisions in NCC 2019, consideration will be given to further opportunities for addressing the risk of condensation. This work will be undertaken in conjunction with the energy efficiency changes for residential buildings planned for NCC 2022. Updated guidance material is also available to assist with minimising condensation in buildings |

|

|

|

|

| |

|

|

|

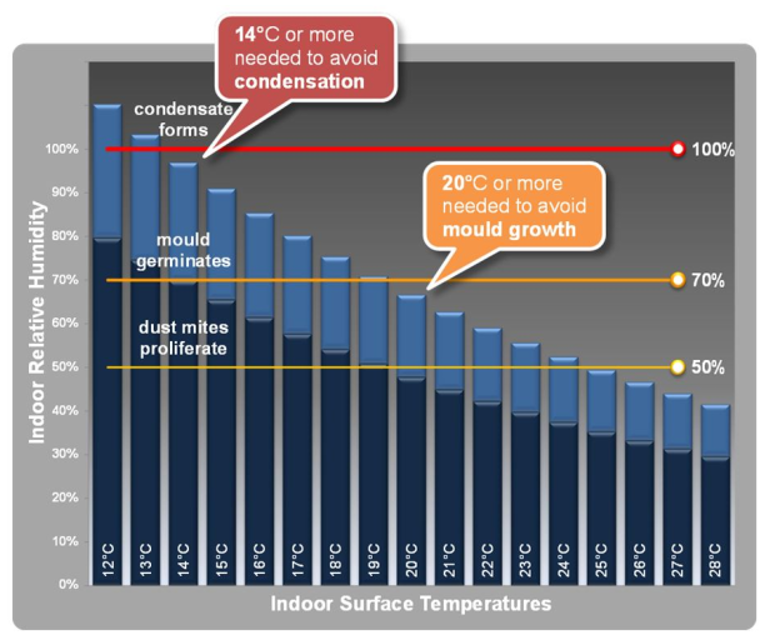

The condensation which is seen mostly in winter seasons at building materials, occurs when the surface temperature of the building material in contact with air falls below the raw temperature of the air. In this case, condensed water may cause mildew, fungal growth, odours, and deterioration of dye and building materials or adversely affected thermal insulation on the walls. Materials used for thermal insulation in buildings constitute resistance against water vapor diffusion. Water vapor diffusion resistance factor (VDRF) of materials can vary over a wide range. In this study, considering VDRF range that is commonly encountered in insulation applications, the effect of VDRF of insulation materials on condensation within constructions, and on the minimum thickness of insulation required to prevent this condensation accordingly were examined. Externally insulated wall was taken as sample wall model, heat and mass transfer calculations from wall unit area and insulation thickness minimization were performed for different indoor-outdoor temperatures and relative humidity values. As a result of the analysis conducted, in constant indoor-outdoor conditions in general, as VDRF increases, the risk of condensation inside the wall first decreases and then increases. Minimum insulation thickness that is required to be applied to prevent condensation also shows a similar trend depending on the VDRF. For constant VDRF, it was come to the conclusion that as the difference between indoor-outdoor temperatures and relative humidity increases, the risk of condensation and consequently required insulation thickness increases. |

|

|

|

|

Managing RH and condensation risks indoors begins with understanding the local climate. The eight climate zones defined for the NCC energy efficiency provisions depend mainly on seasonal temperatures with some attention to summertime humidity. Outside of climate zones 1, 2 and 3, they are not reliable guides when designing and building to avoid high humidity or condensation problems. Chapter 5 examines opportunities to apply, instead, climate statistics available online from the Bureau of Meteorology (BOM) for the numerous locations it monitors and provides suggestions for assessing comparative risk across Australia and the particular characteristics of individual places. |

|

|

|

|

| |

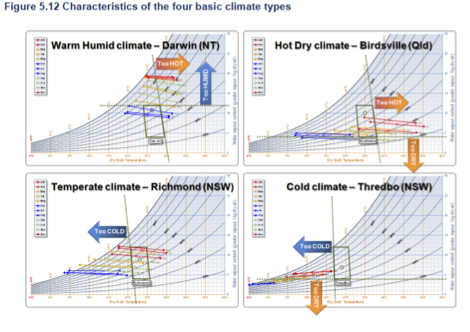

Figure 5.12 Characteristics of the four basic climate typesDistinct differences between the four climate types are quickly evident in Figure 5.12 where the placement, spacing, length and slope of the monthly lines are all significant. In considering what such charts suggest about the nature of the climate and possible responses by building occupants seeking to remain comfortable, the key characteristics to look for are: |

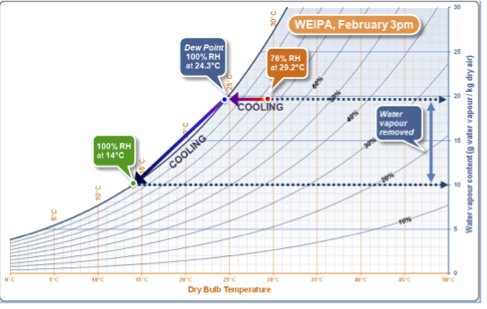

Example:During February in Weipa, the mean outdoor air temperature is 29.2℃ and the mean dew point is 24.3℃ , indicating a RH of 76% (using the mean 3pm data). If this outside air is cooled to 25℃ (with the temperature moving leftwards across the psychrometric chart below), RH rises to 96%. Cooled slightly further, it will reach its dew point and water vapour will begin to condense.Figure 4.10 Psychrometric chart detailing the example of Weipa in February Cooling to any lower temperature will unavoidably remove water vapour by

condensation and lower the water vapour content in the atmosphere. Energy will be

used both to reduce the temperature of the air and to remove the heat (latent heat of

condensation) released by the condensing water vapour. The RH at the lower

temperature will always be 100% but the water vapour content (on the right hand

scale) will have fallen significantly. Mixing the resulting cooled and dehumidified air

with warm indoor air will lower the RH of the water vapour it contains.

Note: Artificial cooling in this climate is likely to include dehumidification limiting

indoor surface risk. External layers of the building fabric in hot humid climates

therefore become prone to condensation if cooling thermostats are set too low.

Cooling to any lower temperature will unavoidably remove water vapour by

condensation and lower the water vapour content in the atmosphere. Energy will be

used both to reduce the temperature of the air and to remove the heat (latent heat of

condensation) released by the condensing water vapour. The RH at the lower

temperature will always be 100% but the water vapour content (on the right hand

scale) will have fallen significantly. Mixing the resulting cooled and dehumidified air

with warm indoor air will lower the RH of the water vapour it contains.

Note: Artificial cooling in this climate is likely to include dehumidification limiting

indoor surface risk. External layers of the building fabric in hot humid climates

therefore become prone to condensation if cooling thermostats are set too low.

|

Hygrothermal modelling

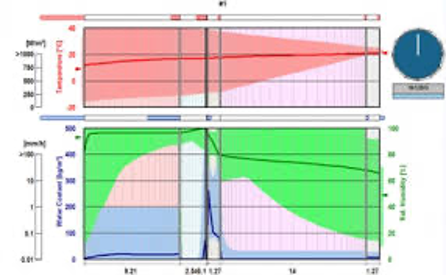

WUFI performs dynamic simulations of coupled heat and moisture transfer. The methods have been validated world-wide and provide realistic simulation of hygrothermal conditions in building components and buildings under actual climate conditions. Developed in Germany, WUFI is the acronym for "Warme - Und Feuchtetransport Instationar" which literally translates to transient heat and moisture transport. So with the magic of computers, WUFI now provides us with the ability to carry out thousands and thousands of calculations to simulate decades worth of real world exposure in a matter of minutes. Don't get me wrong, you really need to know what you are doing to use WUFI properly, (you can be mediocre and use WUFI improperly pretty easily, but do that anyways, because you'll still learn stuff) but let's be clear, this is cool stuff.

- So, what can WUFI tell you? We WUFI things to tell us if we are even close to having a roof or wall that is going to work. If it doesn't work in WUFI, it's not going to work in the field. People have verified this. Even BRANZ has in SR344, a terribly good research study with terribly ridiculous conclusions. Spoiler alert, the conclusion is: the science says most of our walls have heaps of condensation in them, but that cannot be true because no one is reporting it, a terribly scientific conclusion.

- WUFI can also tell you things like whether a material will get wet and dry out fast enough. We can predict the corrosion rate of reinforcing steel in concrete, we can predict the decay rate of timber (even untreated timber, what a concept!) or any other things you might care about in the walls and roofs of buildings.

-

-